So I'd like to discuss some ideas on that. My goal is to create a modular feeder which can be easily attached, and possibly also used standalone for manual pick and place. I think that as a side project it is fairly self contained, and wouldn't require extensive changes to the existing LitePlacer design.

Basically there are two ideas, 1) Keep It Simple! and 2) automatic.

Approach #1. KISS!

This is based on the manual reel holders found on ebay etc:

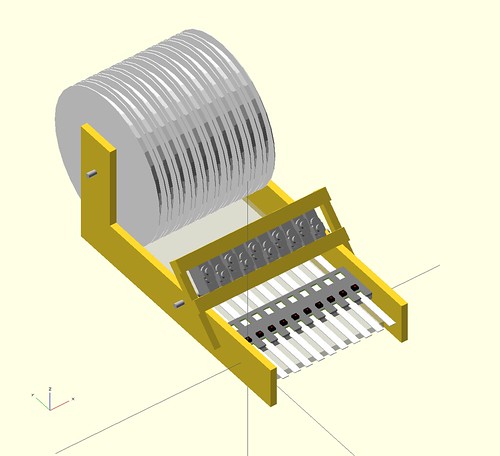

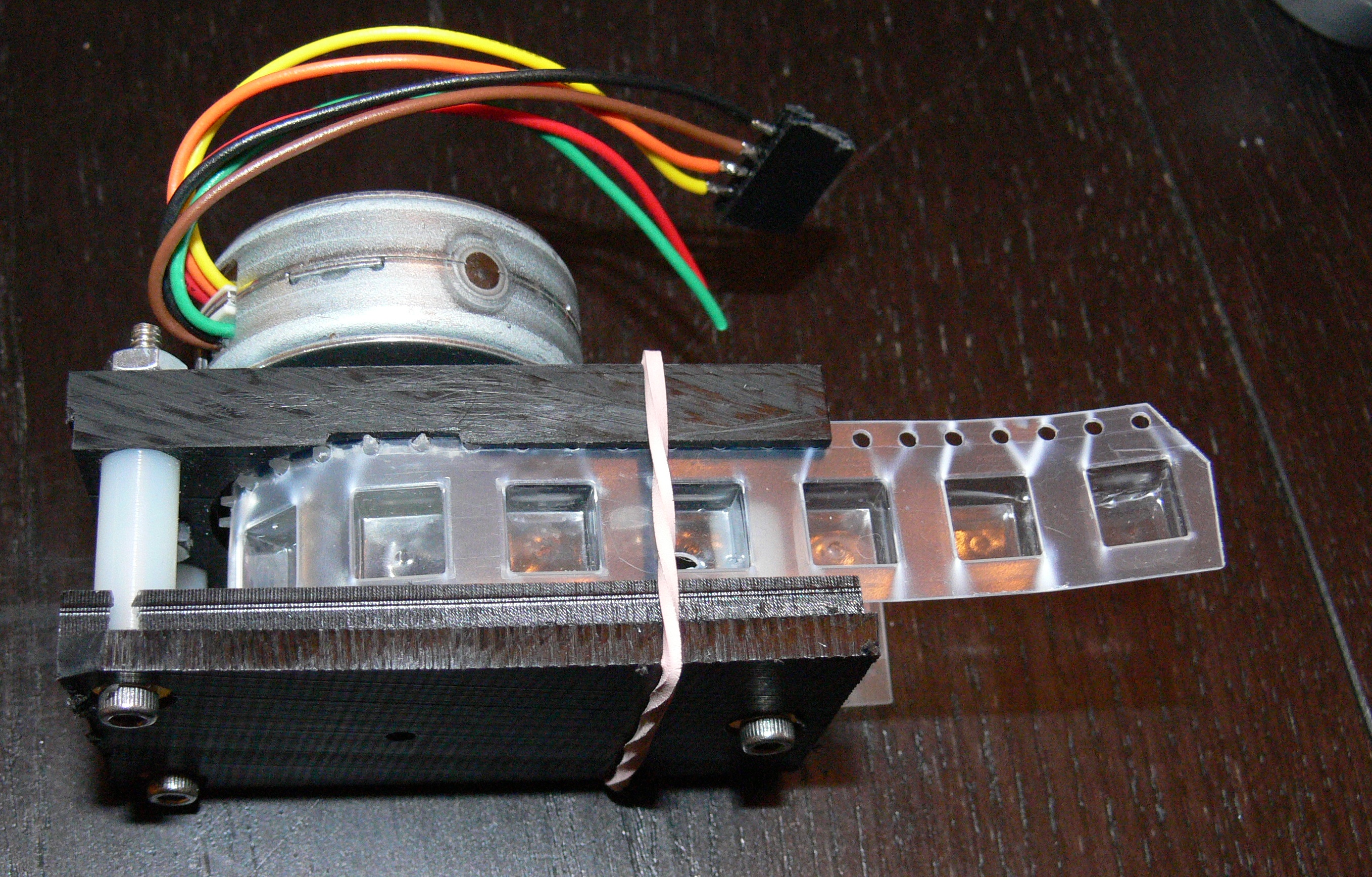

basic_feeder by donotdespisethesnake, on Flickr

basic_feeder by donotdespisethesnake, on FlickrHere is how it could look mounted to machine

basic_feeders by donotdespisethesnake, on Flickr

basic_feeders by donotdespisethesnake, on Flickr(That shows a ShapeOko, but the principle is the same).

Reels can be mounted at side or front, and trays extend across the work area.

Possible to swap modules if different component profiles are required.

Could also be used for cut strips

Advancement: manual. The user exposes as many components as may be needed.

Cover tape: manual. The user must peel off tape and cut it.

Construction: aluminum or plastic to create channels, plus support for reels. Thin rod for axle.

Set up required: only need to align first usable component

Issues:

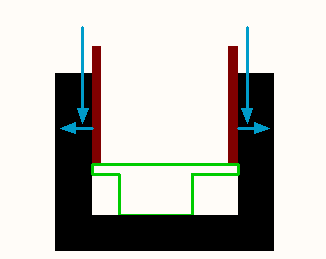

- the tape needs to be held firm against the work top (clamped or spring).

- with a lot of components exposed, it is easy for them to jump out if the tape is knocked.

Conclusion.

This about the cheapest way I can think of mounting a reel.

Need to experiment to see if usable.