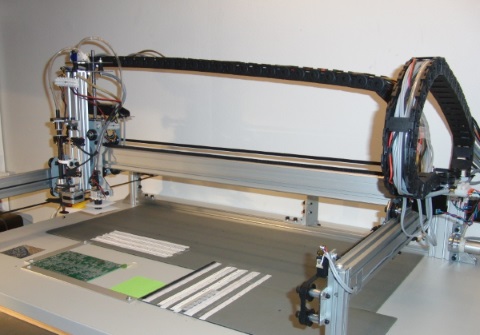

Cable management depends mostly how you want to arrange your work area and where you want the cables to go. The “industry standard” solution is to use cable drag chains, which may or may not be the ideal solution for your particular case. Some notes I have found out:

It might not be necessary to run Y side cables in the air, like I did:

The idea behind this solution was to have both sides of the machine open. I though I would use reel holders and route tapes to the work area from the sides, under the Y rails. I don’t think I’m going to do that on either side and I’m rather sure I won’t do that on the right side.

You can get cable chains from eBay or in US, from Inventables. You can also get a set of chains from my store. My chains, like those from some eBay sellers can be opened from each link, which makes cable mounting easier. On the image you can see that I didn’t bother to put all the lids I removed back in, only for a few. The Inventables chain moves somewhat more fluid than what I’m selling, but does not open.

The mounting pattern on the machine is two holes for M4 screws, 12mm apart.

You need at least 18 x 25 mm space for the cables; more, if you use thick cables.

Some other solutions I’ve seen:

- Flexible pole in the corner of a machine. Looks funny, but offers likely the least resistance and therefore, the fastest machine

- “scissor” type solution: Two long pieces of hardware with a hinge in the middle. I had this on some prototypes. Noting wrong with that, although it does not look as cool as real cable chains.

- All kinds of plastic or other strips of stuff that can flex lengthwise but not very much sideways. If you happen to have some suitable material around, you might save some money.