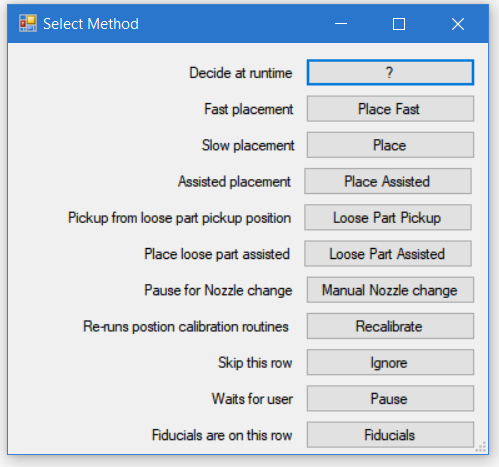

A “Method” tells the software what to do on a row of Job Data. When you click on the “Method” column, you are presented with this dialog:

? – Decide at runtime: If this method is comes up at runtime, this dialog is presented again. At runtime, “?” is not a valid answer.

Place Fast: Measures first and last hole of the tape, calculates the position of each part form these, places the parts on the row

Place, slow placement: Measures each hole, finds the part based on this. Note: Depreciated, the above is both faster and more accurate.

Assisted Placement: Picks up a part and takes it almost to the position. You can then jog the part on top of the exact position. Pressing enter finishes the operation.

Loose part pickup: Picks a part from loose part area, using the specified visual algorithm to recognize part position and orientation and places it automatically.

Loose part assisted: Picks a part from loose part area, using the specified visual algorithm to recognize part position and orientation and places it as described above at “assisted placement”.

Manual Nozzle change: (depreciated) Pauses placement and turns machine motors on. Used with older models of the machine that didn’t have automatic nozzle change and in some special cases. When ready, machine re-homes and re-measures the board.

Recalibrate: Goes to origin, re-measures and resets the machine zero position and re-measures the board.

Ignore: Skips the row.

Pause: Waits for user to do something. If there is a parameter which is a number, pauses only for a number of seconds.

Fiducials: Indicates, that this row has the data for fiducials (position marks, that the software uses to calculate component locations in machine coordinates).