Page 2 of 3

Re: FAQ: Where to get cheap stencils?

Posted: Thu Nov 03, 2016 12:45 pm

by jarekk

Ok, I have tested the new paste - result are excellent.

I would say exactly as on their pictures showing paste application. No detectable flow

One more adjustment on stencil ( a bit too narrow hole for ethernet phy pads) and it will be perfect.

An combined with Vapor Phase Reflow oven - no shortcircuits even on a bit messed tqfp 144

Thanks a lot for really good recommendations !

Re: FAQ: Where to get cheap stencils?

Posted: Wed Nov 23, 2016 11:37 pm

by WayOutWest

jarekk wrote:

An combined with Vapor Phase Reflow oven - no shortcircuits even on a bit messed tqfp 144

What oven and fluid (Galden?) are you using? Do you like them?

I've been thinking of moving to vapor-phase. Would love to hear your thoughts on this.

Re: FAQ: Where to get cheap stencils?

Posted: Fri Nov 25, 2016 5:29 pm

by jarekk

Well, I use galden and the bigger oven from

http://imdes.de/

I like it very much, but you have to be aware of few things:

1) The quality of is very good ( even with big inductors which I had to solder manually before), but the process is much slower.

Takes about twice the time of my previous oven ( so you end up with 9..12 minutes).

2) If you have too much paste ( e.g. too big holes in the stencil), it will not help you much. The stencil must be matched. In my design I had to make it 20% smaller then the pads ( for tqfp144 ).

But it all depends if the footprint was optimized for reflow or manual assembly.

3) You loose galden each time you drain the oven. Takes few ml each time, so you have to consider it in the bill. I might be tempted to use my 3D printer to print gas tight cover to avoid draining it after use.

I had some issues with ordinary SO14 - no connection on some pads unless I was pressing them with my button. The connection on the scope was perfect, but I had to resolder them anyway. Happened on about 8 pcs out of 100.

Still checking it - I even scratched/cut the solder, but no clue. It happened on the circuits close to edge, so next time I will setup temperature sensors on test board to be sure.

Re: FAQ: Where to get cheap stencils?

Posted: Sun Nov 27, 2016 5:50 pm

by Roche

I use an oven I made last year, with Galden. It uses a motorised gantry to lower the PCB into the vapour. Still a work in progress, but I've put several hundred boards through in the year. Because of a combination of transformers, TQFPs and sometimes power devices, vapour phase was pretty much the only logical way to go. The advantages are many. The biggest single disadvantage is the initial cost of Galden...

Re: FAQ: Where to get cheap stencils?

Posted: Wed Nov 30, 2016 3:26 pm

by jarekk

Could you show pictures ?

Do you loose much of Galden during soldering ?

Do you keep it in vapor phase all the time and just put boards one after another ?

Re: FAQ: Where to get cheap stencils?

Posted: Wed Nov 30, 2016 6:23 pm

by Roche

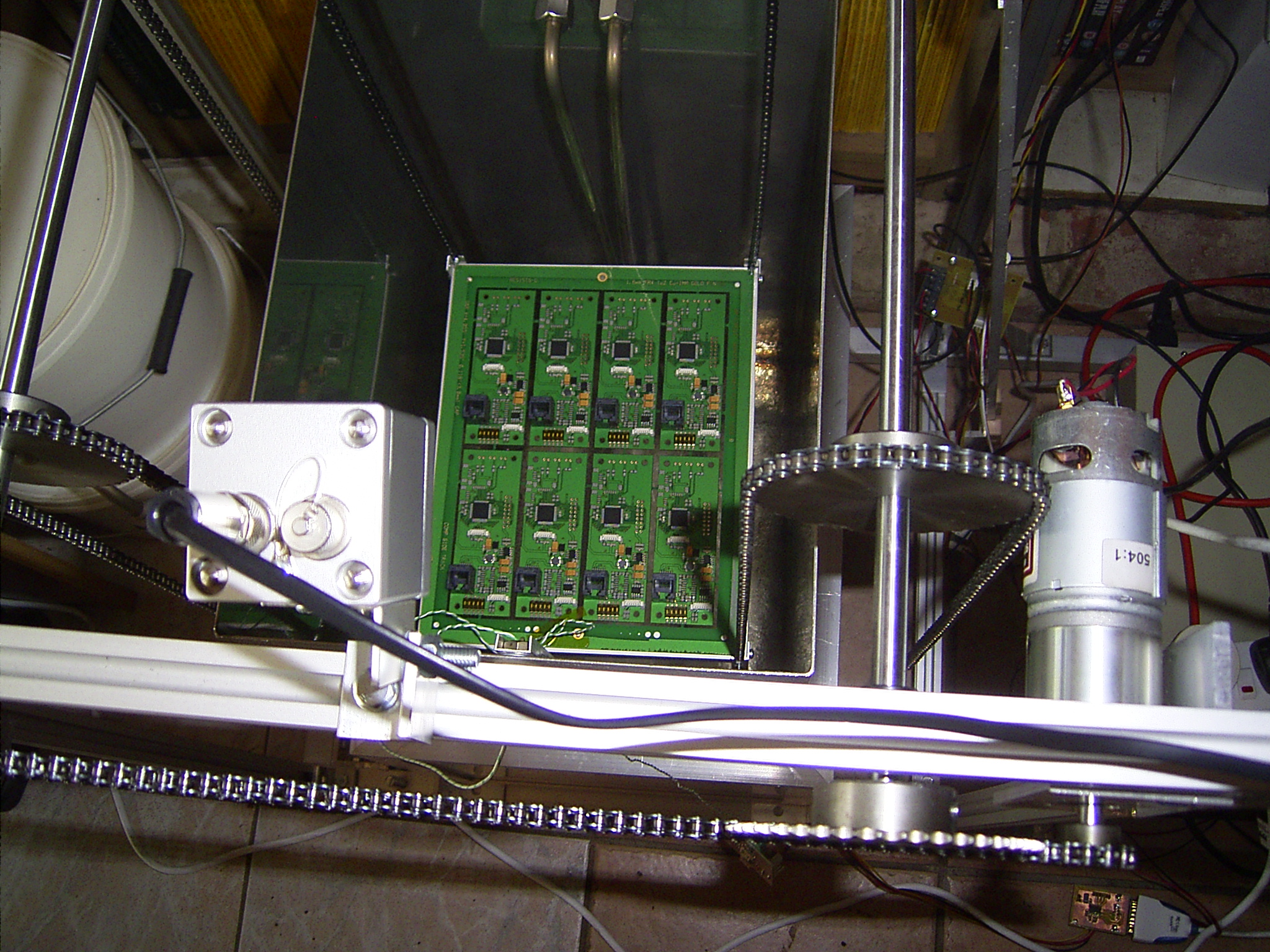

- Pic2.JPG (1.27 MiB) Viewed 22810 times

A panel in transit.

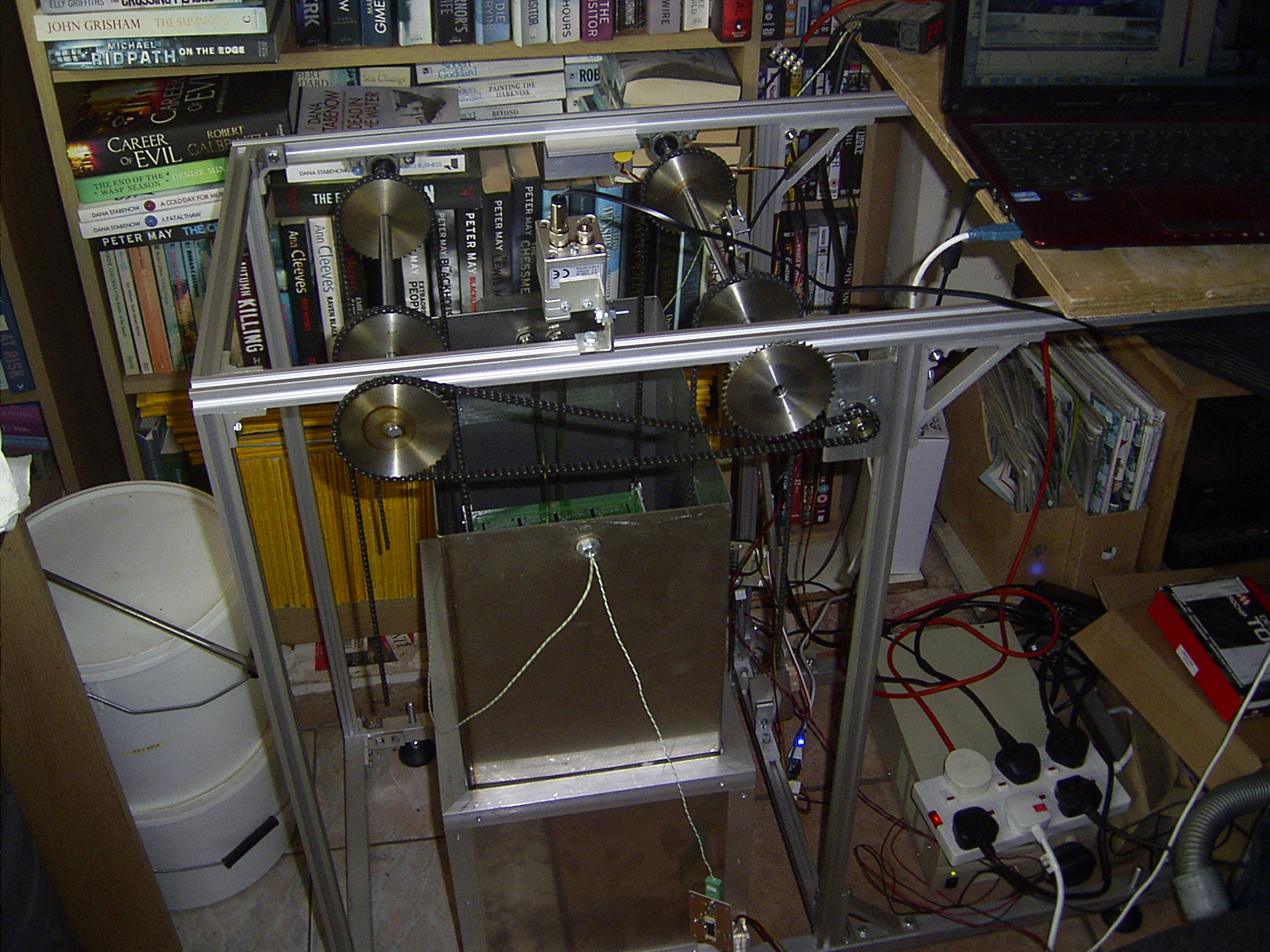

- Pic1.JPG (1.28 MiB) Viewed 22810 times

General view - the base is insulated with refractory insulation to reduce heat loss.

- Pic3.JPG (1.24 MiB) Viewed 22810 times

I tried using a thermal imaging camera to view reflow - It doesn't work. Once the panel is in the vapour only the surface of the vapour is visible.

I loose a little more than I would like - The next lump of work is to reduce that by shifting the lifting mechanism into the tank.

The system can stay heated with successive panels being fed in, or heated per panel.

Re: FAQ: Where to get cheap stencils?

Posted: Thu Dec 01, 2016 8:36 am

by jarekk

Nice one.

I loose most of Galden when draining the oven - that is why I plan make gas tight cover, so it can be left there.

I think some is lost also on boards - especially in my case when I have to cool down whole system ( before taking out the board ).

Nice collection of Lee Child's books

Re: FAQ: Where to get cheap stencils?

Posted: Thu Dec 01, 2016 10:25 am

by Roche

I leave the Galden in all the time - there is a perspex cover for the tank. The next modifications are shifting the shafts and sprockets inside the tank, with the shafts protruding from the tank for the drive to be attached. I also have a cooling circuit ready to go on around the top of the tank. These changes will mean that the perspex can stay on all the time, apart from when the PCBs are being swopped.

It all works pretty well. There is a little bit of tombstoning, which I suspect is due to profile - there needs to be a better pre-heat. I am trying to do that using the height above the Galden, but there is very distinct and sharp stratification - even a 1mm change makes a significant temperature difference.

Re: FAQ: Where to get cheap stencils?

Posted: Thu Dec 01, 2016 11:31 am

by jarekk

I have not had tombstoning at all ( over several thousands of resistors). My oven preheats the board a bit ( around 100 deg ), although I would have to check how it really works as galden is not activated in that temperature. I will place probe on the board next time.

Professional Galden based ovens seem to have convection zone for it.

Re: FAQ: Where to get cheap stencils?

Posted: Thu Dec 01, 2016 7:03 pm

by Roche

I had been hoping to avoid putting extra preheat elements in, but I might still do it as a last resort.