mawa wrote:Your question gives the answer to the jumping. When I used the holders without suitable support below the pockets the tape was not fixed very well at its edges. Therefore the downward probing pressure led to a bending kind of deformation that snapped back when the head move back up.

Don't get hung up on my feeder design - I think John's mechanism to hold the tape is superior to my approach. With my feeders the fixation of the tape depends on fastening the screws carefully; in John's design this is overcome by the spring and slider mechanism. Bottom line is: If the edges of the tape are well supported and pressed against the top rail with sufficient force, I don't think we will see issues with vibrations and "jumping" parts.

I also think that the probing force is too strong; so manually setting Z-level for pickup (which would be identical for all strip feeders anyway) could reduce the problems.

JohnSL wrote:About the fiducial markers. I could certainly include some feature in the injection molded part. How well could the camera pick this up, though, if it's the same color as the rest of the strip holder? In other words, I'm still not sure how to handle this.

To detect a feature visually, it needs to have some contrast relative to its background. Where would you put such feature? I think circular would be best as it is easy to visually find the center of a circle...

Ideas:

- Could we have an indentation on the feeder and colour this later (thinking black fine marker or similar)?

- Other option would be to mold a small cylindrical "pin" in different color and press fit this into the side wall.

- Third option I could think of would be to have a "snap on clip" (like for the sprocket hole index pin) on both sides of the feeder; this clip could also hold fiducial markers. So front clip would have a tab for QR code and fiducial, back clip only fiducial.

Edit: Now that I think about it, option 3 might be the best - as that clip could serve more purposes as outlined below.

JohnSL wrote:I made the opening 0.4 mm wider so there would be some clearance for the widest tapes. However, this means that a tape that is actually 8 mm wide might not be aligned exactly in the slot. Instead it could be off by +- 0.2 mm.

I think that at the front end the index pin makes sure the tape is in the right location, both left / right and back / forth. Sprocket hole vs. part pocket location is usually a very tight tolerance. So why not add a similar clip at the back end of the feeder as well?

This secondary clip (and the holding features in the side walls) could be made in such a way that the clip could slide back and forth. The sliding would be necessary as there is some tolerance in sprocket hole spacing (in tape direction), too. If we could slide the clip even further, we could support shorter tape strips.

Both clips together would nicly align any tape strip parallel to feeder orientation; as the front clip would be fixed, it would ensure the first part position.

JohnSL wrote:So I think there is a good chance I'll be able to have the parts made in green (I'm thinking a lighter green like used for green screens in the film industry).

I'd vote for black side walls, spacers and clips - just because it looks better. Only the sliding support rails should be green - if at all. I still doubt that we need to visually detect the sprocket holes once we have auto setup in software. Detecting fiducials and QR code on the feeder sounds more reasonable to me.

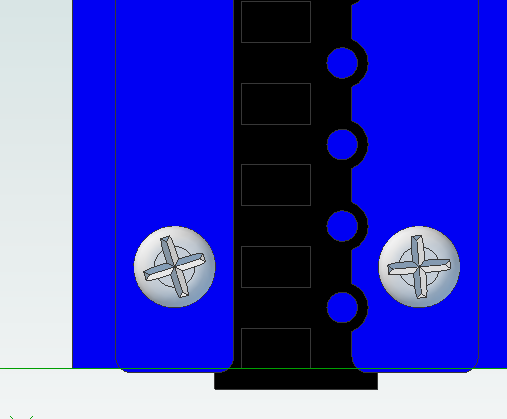

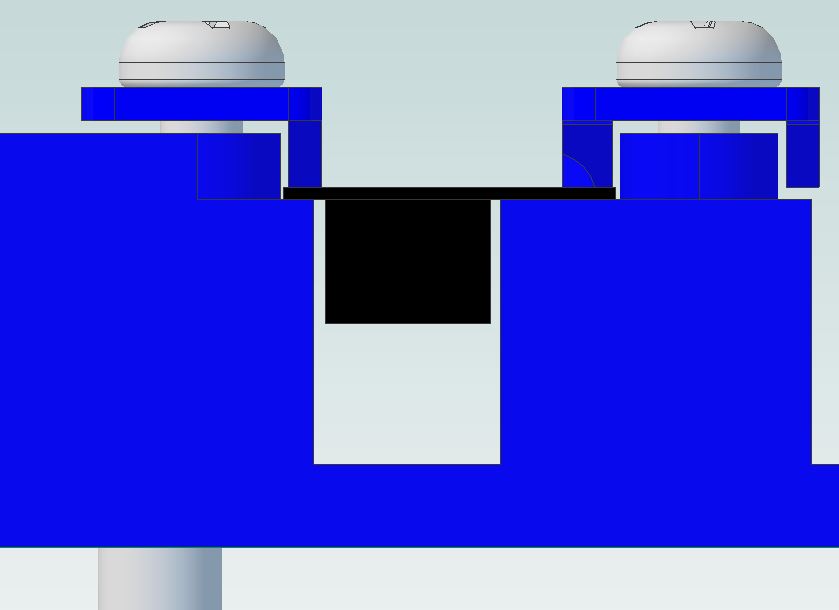

Last point about sprocket holes: When I designed my feeder, I had some trouble with the tolerances of the rails which are meant to hold down the tape. I did not want to cover the sprocket holes, but still wanted a tight hold on the tapes.

I ended up with the following:

- feeder_cutouts.png (22.8 KiB) Viewed 27002 times

- feeder_side.png (25.68 KiB) Viewed 27002 times

I think you might run into similar problem. Making the rails wider means the tapes will be held more firmly; but might cover the sprocket holes.

IMHO this also supports my argument for ficudials on the feeder itself; because if we had those and the software supported it, we would not have to care about the sprocket holes being visible.

Even if fiducials were not visible, we could still "teach" the software the first and last part location - this is how most commercial machines are being setup for strip feeders.