Hi everyone,

I've been somewhat quiet because I've been waiting for quotes on injection molds. I just got one quote from a company here in Washington state that was a lot higher than I expected. Based on previous experience from about 10 years ago, I was expecting the molds to be in $5,000 to $10,000 range, as these are very simple molds to make. The quote came in well above that figure. They also quoted about $3.00 for a set of parts, which seemed quite high. I think a lot of this was because of the material they chose. I asked them for an anti-static plastic, but they asked me to supply them with a source. I found one source of information, and apparently that was a pretty expensive material.

GaryM wrote:I have no connection to the company, I just have them bookmarked for some possible projects for my own business.

http://www.star-prototype.com/

I've also requested a quote from Star Prototype, and they said they should have a quote for me on Monday, so we'll see what they come up with. I asked Star Prototype for an anti-static plastic and they said no problem and asked if ABS would be OK. Since I wanted ABS, that fit perfectly.

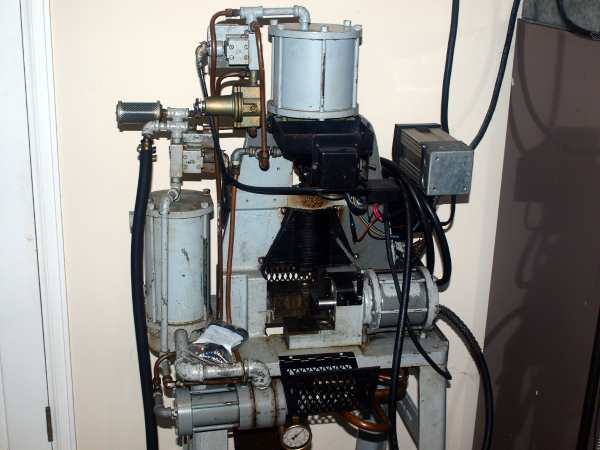

I have no idea if the market is large enough to support the those estimates, so I've been looking into other options. I have an injection molding machine I purchased via eBay a few years ago but never got running:

- PC102145_500.jpg (41.08 KiB) Viewed 22319 times

This is a Simplomatic PRO63, which is billed as supporting semi-automatic as well as automatic molding. It supports much bigger molds than my other machines. I don't know a whole lot about this machine as it didn't come with any documentation. However, with some searching, I've learned that it has a 7,000 psi injection pressure, 6 ton clamp, and 1/3 ounce injection capacity.

The largest part requires 0.26 ounces of material, so we're within the specs of the machine. The surface area of that part is 4.62 square inches, which means that at the 6 ton clamping force the maximum injection pressure I could use would be 2,600 psi if I've done my math correctly. I think that will work. I have another injection molding machine that I've used for "larger" parts I've made:

http://www.travin.co.uk/tp1.html. On that machine I've made some parts with a surface area of 4.9 square inches, but only 1 mm thick (sorry for mixing imperial and metric). For these parts I had to bolt the mold halves together because the clamp on the machine wasn't strong enough (I think it's a 4 ton clamp if you have everything set up correctly and use a lot of muscle to close the clamp). I also know that thinner parts require more injection pressure. The larger parts for the strip feeder have a nominal thickness of 2 mm, so should require less injection pressure. The Travin could probably make the parts, except for one issue: the Travin supports 4 by 3 inch molds, but these parts are about 5.5 inches wide. I think the PRO63 should have no problem at all making parts.

The other issue is that I need to use pre-colored plastic pellets because none of my machines have screws. Most injection molding machines uses screws, which allows mixing the plastic with additives like colorants or anti-static material before injection. But I don't have that. Or do I? It turns out I have a filastruder kit that I never assembled, and it does have a screw. So my thinking is that I could use this to mix raw ABS with colorants and anti-static additives to create the correct material. And, instead of producing a roll of filament, I could easily add a "cutter" that would cut the filament into small pellets while the material is still soft. Then I can use the resulting pellets in my injection molding machine.

So, I have two questions. First, does anyone happen to know more about the Simplomatic PRO63 machine? Second, any suggestions on other companies to contact about injection molding?