Automated rotation correction

Posted: Wed Feb 25, 2015 5:37 am

I'm interested in your kit, and have questions on the software:

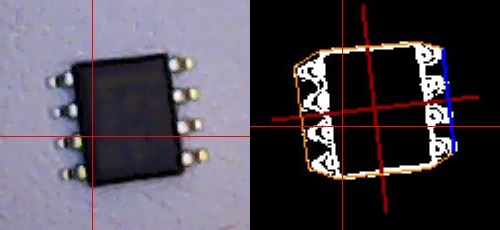

it seems to me that a pick and place isn't very valuable until you add a lot of image processing and recognition routines. It is unclear to me based on your website about how much you've been able to implement with regards to your downward and upward looking cameras.

these cameras and their software are the most important aspect of a pick and place. the software needs to be able to:

1.) accept a set of part center coordinates from a CAM file from eagle, or whatever pcb tool you use - this file will be slightly wrong in x,y, and rotation

2.) use the downward looking camera to go through and manually update / calibrate the real positions that you tell the software, based on what you see on the camera for both the part pickup location, and the part placing location on the board; the software would then do all the coordinate transforms necessary to be able to continue (x,y, rotation, etc.?)

2a.) you only need to do this one time for each job that you're gonna run

3.) the upward looking camera must be able to correct for part rotation, and center location for anything from a 0805, to a tssop micro, to a bga part. right now I see that you have an upward looking camera, but your site or videos don't really show it doing these corrections.

right now, in your video, I see a machine that places parts at an x, y coordinate based on the cam file, but I didn't see you calibrate each location, and I didn't see the machine verifying and correcting x,y, and rotation for parts using the upward looking camera

how far along are you on these software capabilities? maybe I just missed a section of the site explaning that these features are working quite well already.

an x, y gantry machine is one thing, but the software to drive a proper pick and place is really where the need is at to take it from a hobby level machine, to a real contender.

i'm interested in buying a kit, but am skeptical at this time, not having seen clear and confident presentations of the above camera / software capabilities - can you show us what's possible?

it seems to me that a pick and place isn't very valuable until you add a lot of image processing and recognition routines. It is unclear to me based on your website about how much you've been able to implement with regards to your downward and upward looking cameras.

these cameras and their software are the most important aspect of a pick and place. the software needs to be able to:

1.) accept a set of part center coordinates from a CAM file from eagle, or whatever pcb tool you use - this file will be slightly wrong in x,y, and rotation

2.) use the downward looking camera to go through and manually update / calibrate the real positions that you tell the software, based on what you see on the camera for both the part pickup location, and the part placing location on the board; the software would then do all the coordinate transforms necessary to be able to continue (x,y, rotation, etc.?)

2a.) you only need to do this one time for each job that you're gonna run

3.) the upward looking camera must be able to correct for part rotation, and center location for anything from a 0805, to a tssop micro, to a bga part. right now I see that you have an upward looking camera, but your site or videos don't really show it doing these corrections.

right now, in your video, I see a machine that places parts at an x, y coordinate based on the cam file, but I didn't see you calibrate each location, and I didn't see the machine verifying and correcting x,y, and rotation for parts using the upward looking camera

how far along are you on these software capabilities? maybe I just missed a section of the site explaning that these features are working quite well already.

an x, y gantry machine is one thing, but the software to drive a proper pick and place is really where the need is at to take it from a hobby level machine, to a real contender.

i'm interested in buying a kit, but am skeptical at this time, not having seen clear and confident presentations of the above camera / software capabilities - can you show us what's possible?