We need two Y pulley subassemblies. Therefore, repeat the following three pages twice.

Take Y pulley plate and ensure, that a 608ZZ flanged bearing fits to the big hole. You might need to use a file to smoothen out any laser cut remains. The fitting is tight and the bearing could “snap” in to position. Push the bearing in the direction indicated, just in case it gets stuck in the hole. If it does it is ok. If it doesn’t it is ok as well, we’ll secure it to position later.

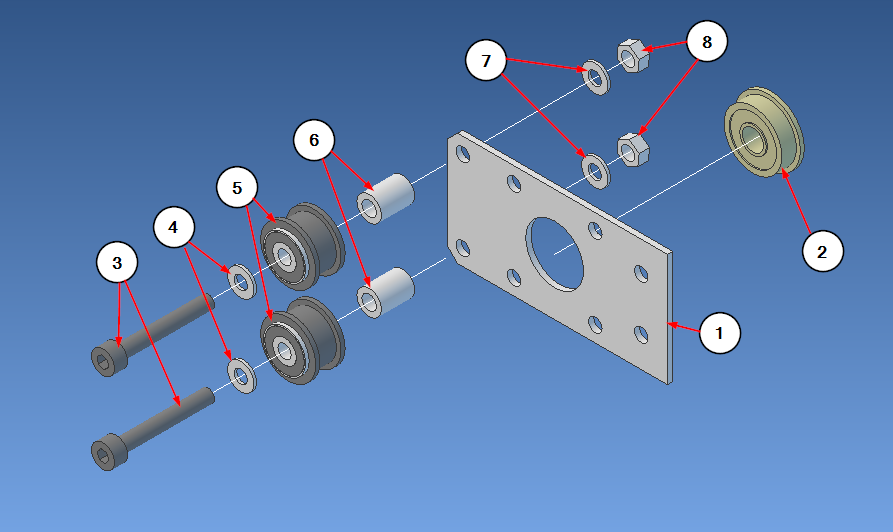

Attach two idler wheels to the plate as shown. Using M5-35 bolts, put to each bolt a washer, an idler wheel (note the orientation), an 0.5″ aluminum spacer, the plate, a washer and a nut:

- Y pulley plate

- 608ZZ flanged bearing

- M5-35 x 2

- M5 washer x 2

- Idler wheel subassembly x 2

- aluminium spacer, 0.5″ x 2

- M5 washer

- M5 nut