Select downlooking camera to the display window.

Set focus and camera height

The cameras have a manual focus ring. First, untick “Show pixels”. Play with the height and set it so, that the largest component you are or think you will be using fits to the image, with some room to spare. Tighten the height adjustment and focus to the surface level of a PCB. Do not refocus on next steps.

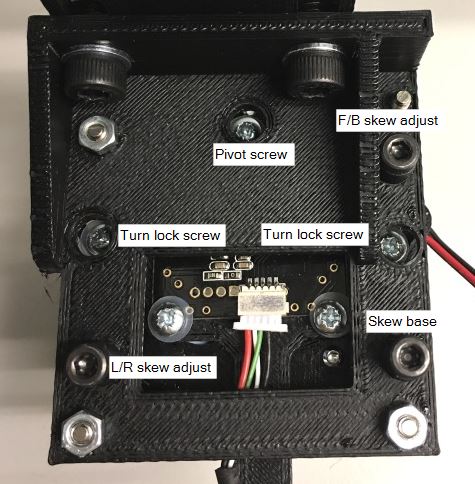

Camera adjustment screws

Here is an image of the camera assembly, showing the adjustment screws:

Align the Camera

Select the “Draw Cross” tick box; this draws the red alignment cross on the image. Put a ruler on your table, and adjust its position or jog the machine so that a point on the edge of the ruler aligns with the center of the cross. (Hint: At this point, you might put a needle to your table and support that point of the ruler against it.) Move the machine in left-right direction to the other end of the ruler. Adjust the ruler so, that at both ends, the ruler edge aligns with the center of the cross. Your ruler now aligns exactly to the machine X axis. Adjust the camera lever so, that the horizontal red line is parallel to the ruler edge. With a small posidrive screwdriver, tighten the turn lock screws through the holes. Re-check that the alignment is good and tighten the pivot screw.

Put a mirror on the table under the camera, so that you see the camera module on the image. It will be out of focus, but you should still be able to do this trimming. Do not refocus. Also, you might want to turn off the lights or add some non-reflective stuff on the mirror to prevent the strong reflection from the LEDs. The camera module is spring loaded at three points. Don’t turn the skew base screw. Turn the two skew adjust screws so, that the center of the camera is at the center of the cross. The camera is now looking directly down.

Add diffuser

When you are happy with the focus and alignment, add the diffuser assembly. The goal is to minimize the effects of reflections from the LED light. Using the additional supplied standoffs is optional; use what gives you the best results. Put a blank PCB under the camera and see yourself. Attach the diffuser assembly to the camera unit. Be careful not to change the camera adjustments. Note, that the standoff positions are not symmetrical. The standoff that is farther off from the corner than the others goes to left back.

Set the Camera Units

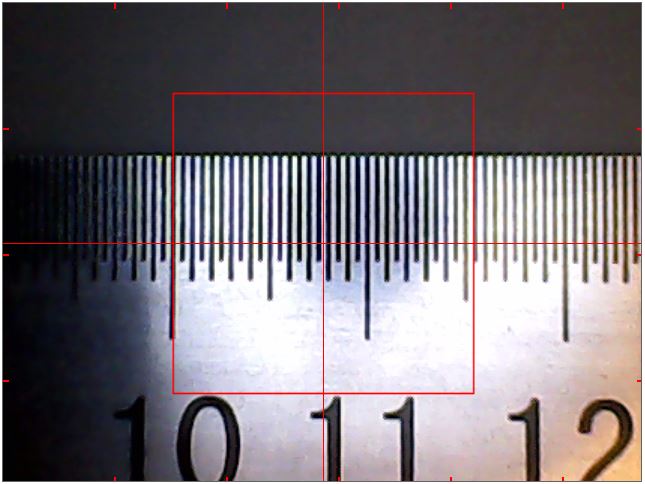

Select “Show pixels”. Check the “Draw Box” tick box and adjust zoom to less than 2 or turn it off, so that the box fits in the image. Put a ruler under the camera or use a caliber to measure the box size, like this:

Put the true size of the box (here I put in 15.4mm) to “Box X” and “Box Y”. (There shouldn’t be a big difference in X and Y, if any.) Your machine now knows the size of things it is looking at. (Please note that for now, the image is from earlier low res cameras; your box size will be smaller.) Also, please note that when we get to the measurements using camera, you might want to get back to this: You can measure an object of known size (such as a fiducial on a PCB, a washer or something similar) and get results in pixels. This will allow you to check or change the mm’s/pixel measure.