As I was wiring the machine today (for start I mount the original camera) I wanted a solution for a better mounting of the ring led's, because I want my machine to look as lean as possible (i'll share more of my ideas later when there's more progress).

The ring led doesn't fit well on the camera mount; smd resistors or wiring is making contact with the aluminium mount, and I don't like the foam tape solution. I was first thinking of making some bracket with my laser cutter, or some pvc ring would do in between... looking through my workshop I saw the perfect part !!!

I used a soldering wire spool, cut it in half, mounted a rubber ring inside (they are used to protect wires in panel mount) the bigger ring on top of the ring led pcb is to hold the ring led's in place, if you haven't got such a big ring or cannot find them in your local store you could easily use some hot melt glue to keep it in place.

This way you've got your ring led mount and diffuser all in one piece! I didn't power it up yet, but I'm convinced this is the best solution I can think of, by the way: using this 'trick' you've got a second mount as a spare or share

here are some pictures, and please share your feedback with me.

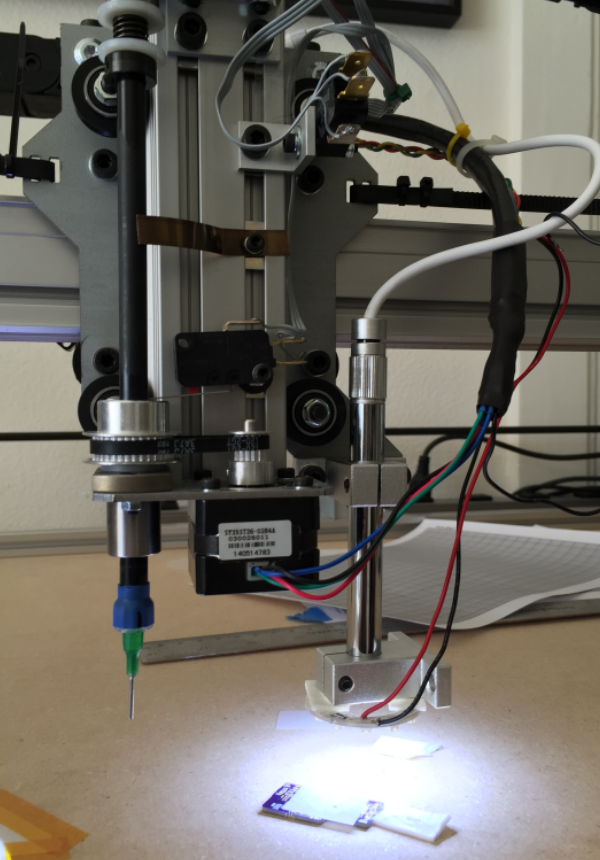

- assembly mounted on my machine

- IMG_0925.JPG (43.16 KiB) Viewed 31222 times

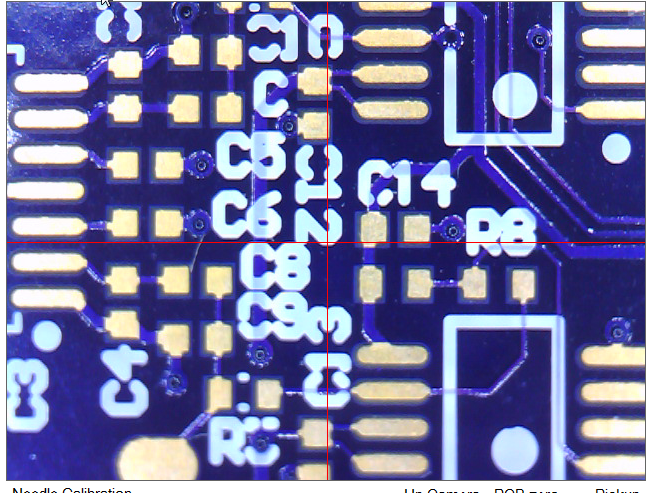

- completed assembly

- IMG_0922.JPG (40.64 KiB) Viewed 31222 times

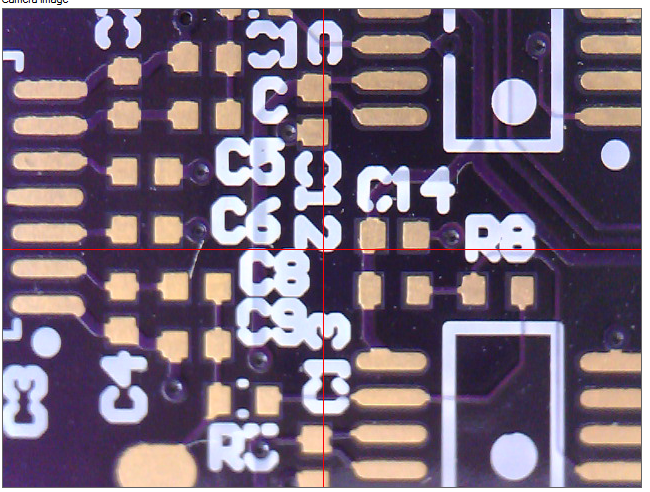

- used parts

- IMG_0921.JPG (39.75 KiB) Viewed 31222 times