Bad news: No matter how well you tried to get the machine to be square at assembling it, you failed (especially because I told you to care more about smooth movement than squareness). Without sophisticated equipment, it is almost impossible to get a mechanical machine to be square enough for the precision required from a pick and place machine. Good news: The LitePlacer is a sophisticated equipment.

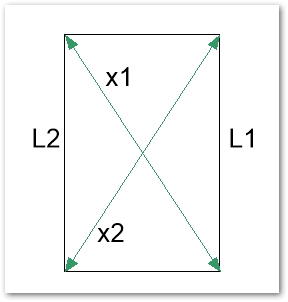

First, you need a truly square reference. Most people don’t have a good square, but for calibration, paper sheets work perfectly well. Most office paper sheets I’ve tried have been good enough. Take a look of the following diagram; if the sides (L’s) are equal and the cross measures (X’s) are equal, the reference is square:

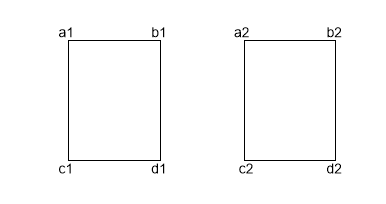

You can easily check for this. Take two sheets. The corners are a, b, c and d.

Turn one sheet over, so that b2 goes over a1 and d2 over c1; this also takes c2 over d1. Place the sheet on top of each other. If the sheets still match, the sides are of equal length. Now turn the top sheet clockwise, so that b2 goes over b1 and c2 goes over c1:

If the corners match as well, you have a good reference.

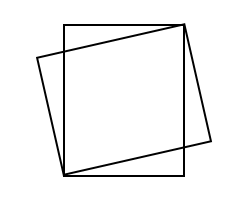

Now, put your reference on your table, and align its edge precisely to the machine X direction: When you move the machine in X direction the reference is set up correctly when the center of camera image travels precisely along your reference edge. Now, take the camera to the corner of your reference. Move the machine some known amount in Y direction only (for example, 2 x Alt+Shift+F7 is 200mm). Unless you were really lucky at assembly phase, you notice that the reference edge does not quite stay in the image center. Using the F5/F6 arrow keys (0.1mm per press), move the image to match the edge, making note how much you needed to move.

Calculate the amount of correction needed. For example, if you moved 200mm and needed to move 0.3mm to right (positive direction), the correction is 0.3/200 = 0.0015. Put this number to Basic Setup, Squareness Correction box.

The System will now use this value, and correct movements on the fly(*), giving you a perfectly aligned machine. You are welcome.

*: The exception is jogging the machine with num pad keys. In this mode of movement, the squareness correction is not applied.

Previous (Nozzle tip to camera)